Fixed Gas Detection.

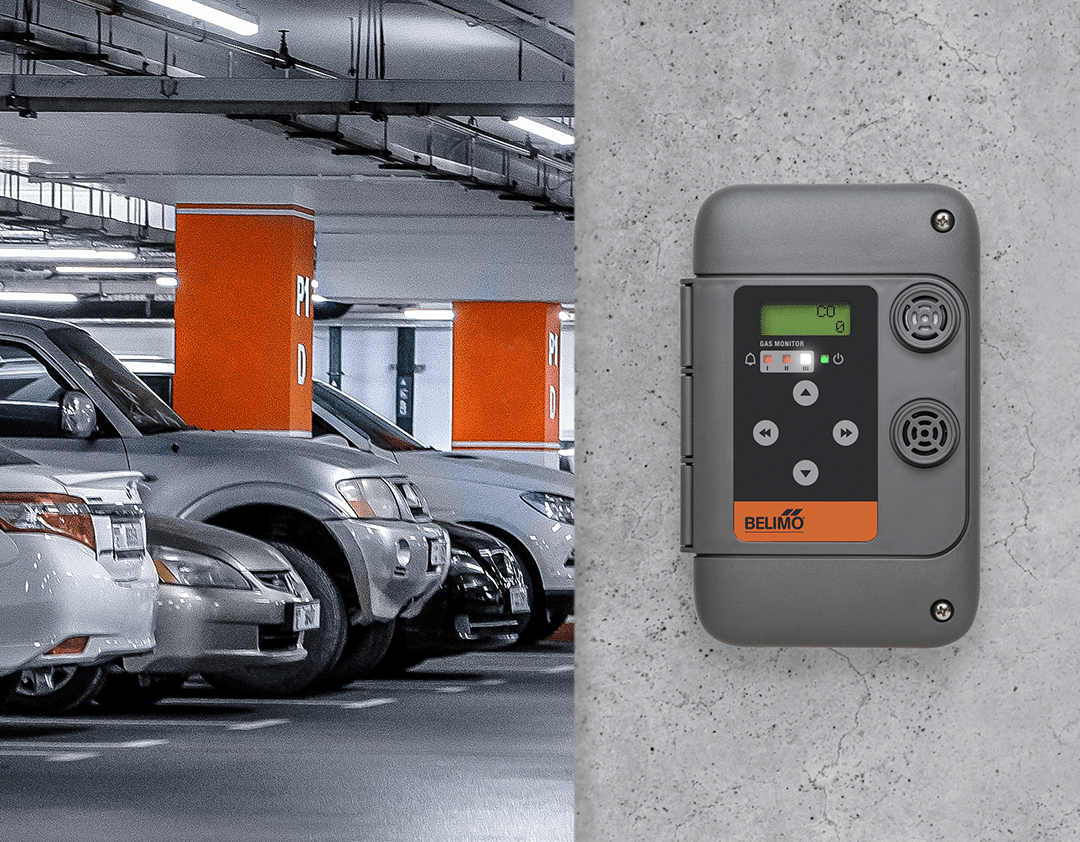

We provide fixed gas detection solutions for diverse applications, from corrosive and hazardous environments to commercial and industrial spaces like parkades, arenas, and workshops.

Knowledge and Experience to Find the Best Solutions

With the acquisition of Detection Measurement Systems (U.S.) and Concept Controls (CAN), Paradigm HSE specializes in fixed gas detection systems for a variety of applications, including commercial and industrial. We cover every aspect of your gas detection requirements, from sales and consultation to commissioning and on-site calibrating. Our technicians are factory-certified and trained for the highest level of service, including confirming sequence of operation for each gas detection system. We go the extra mile to ensure your building is safe and healthy.

Areas of Gas Detection Service

- Arenas

- Automotive Dealerships

- Mechanical Rooms

- Chemical Storage

- Swimming Pools

- Oil and Gas

- Parking Garages

- Warehouses

- Hospitals

- UPS Rooms

- Airports

We carry high-quality products from trusted brands

Gas Detection Consultation & System Design

Whether you are in need of parkade gas detection specifications, arena upgrades, or consultation on the most appropriate make and model of equipment, we’re here here to make your job easier and prevent unforeseen problems and costs.

Our experienced senior staff and certified electricians can provide consultation during the building design process and prior to tender, purchasing, installing, or upgrading, and recommend the best products for your application.

They will also ensure that the placement of the equipment is appropriate and that the installation procedure goes smoothly.

Calibration and Servicing

Industry best practices for optimal performance of a gas detection system recommends scheduled semi-annual calibrations. Depending on the type of sensors, as they age they will drift towards either greater or lower sensitivity. Sensors that drift towards greater sensitivity result in the ventilation system unnecessarily running more often, increasing energy costs. Sensors that drift into lower sensitivity result in the ventilation system responding slowly to toxic amounts of gas in the air, creating a health and safety issue. When we do calibrations, we apply a test gas to the sensor and make the required adjustments to the detector to keep it operating at the optimum efficiency. This results in a safe and healthy building that has the highest level of energy efficiency. Frequent calibration also keeps the detectors operating at their optimum level. Generally this will produce longer sensor life, reducing the capital expenditures of replacing the sensors and creating tangible savings due to lower utility and operating costs.

We also realize that factors such as model and age of equipment, operating conditions, and so on may impact the calibration schedule. By looking at all the factors that affect sensors, including the number of detectors providing coverage, we advise on an appropriate calibration schedule—two, three, and four times annually, or more frequent in demanding applications. Safety of the public, on-site personal and building health is priority number one.

Recent Projects

Parkades

Arenas

Workshop Maintenance

Fresh Air Dampers for Big Vehicles

Industrial/ Commercial Gas System Sales

I wanted to say thank you to the team that has put together the ASTI training sessions in Calgary. My thanks is long overdue, but heartfelt. This was the best training that I have received in my 25 years in the refrigeration trade. This training is changing the ammonia industry – it is creating a safer, more competent, more uniform and better prepared workforce.

Paradigm has consistently upheld its commitment to quality of services, support, and timely response for all of the Devon Research Center gas detection system programming and calibrations needs; and it is a first class service we’ve come to expect.